Inspection Services (QA/QC)

Digital Scan 3D LLC (DS3D) has highly trained and experienced staff to perform practically any inspection service project.

We can inspect and analyze your parts in a variety of ways:

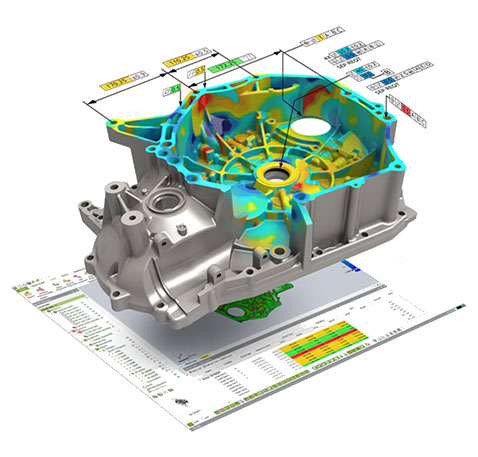

- 3D Scan to CAD Inspection

- First Article Inspection

- In-Process Inspection – Production Parts Inspection/ Production Part Approval Process(PPAP)

- Dimensional Inspection/Analysis

- Tool/Mold Inspection

- Verify the compliance of final manufactured and assembled products through sample check inspection using automated techniques.

- Monitor the production cycle by automatically measuring the wear of tools and quickly detecting any abrupt degradation in product quality.

- Use high-density point clouds and contact-probe datasets of digitized prototype parts & assemblies to quickly identify deformations and to fix problems in the earlier stage of the manufacturing process.

Types of Inspection

- 3D Scan to CAD Comparison

- 3D Scan analysis with 2D drawing aid.

- 3D Scan to 3D Scan (Mesh) analysis.

- Probing & CMM

Digital Scan 3D offers metrology services and implements metrology equipment from the 3D scanning industry’s leading manufacturers. Our highly trained team can configure and recommend our comprehensive lineup of portable 3D scanners: white light scanners to blue light scanners; 3D laser scanners and 3D desktop scanners & digitization equipment and software for any application.

Project Delivery

- Small Projects: 24 hrs. Scanning & QA/QC on a couple parts

- Medium Projects: 48 to 72 hours on Standard small projects for both 3D Scanning & Reverse Engineering

- Large Projects: 3 days+ as agreed.

Our team of measurement specialists has a diverse and lengthy background in the use of 3D measurement technology systems and metrology software packages.

We utilize the latest in 3D software including Polyworks and GeoMagic. We also sell the software packages, offer training both onsite and offsite. Digital Scan 3D is continually adding the latest in equipment and software to our inventory to meet our customers’ needs.

Quality Control (QC) is a set of activities for ensuring quality in products. The activities focus on identifying defects in the actual products produced.

Quality Assurance (QA) is a way of preventing mistakes and defects in manufactured products and avoiding problems when delivering products or services to customers. Quality control, therefore, is a reactive process.

Industrial design and manufacturing

Reverse engineering

Quality control

Rapid prototyping

Aerospace

Healthcare

Orthopedics

Prosthetics

Plastic surgery

Custom wheelchairs

Science and education

- Research

Training

Online museums

Art and design

- Heritage preservation

Architecture

CGI

Fashion