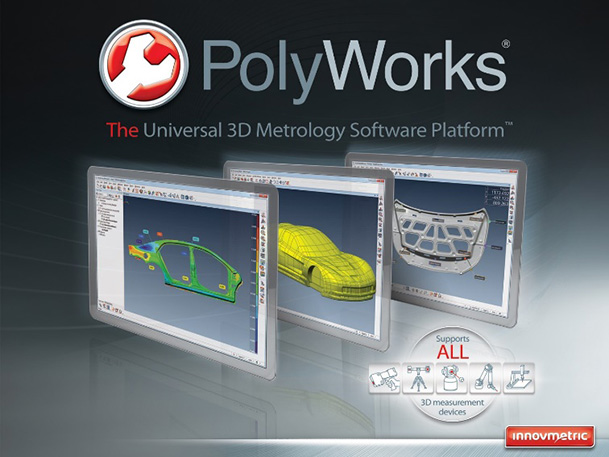

Polyworks

PolyWorks Inspection Software

PolyWorks | Inspector™ is a universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.

Universal Software Platform – With just one software to master, dramatically reduce your operational costs by increasing measurement specialist competency, eliminating metrology silos, boosting employee mobility, and improving overall teamwork efficiency.

Polyworks Total Solution – One-Stop Metrology Solution

Xtreme User Interface Customization

Complete Usability

PolyWorks Inspection Software

Interface with all 3D measurement devices thanks to a universal digitizing hub

Deploy universal inspection projects playable on any 3D measurement device

Perform all inspection tasks using a universal 3D metrology workflow

Complete Dimensional Analysis and

Quality Control Toolbox

At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, certified mathematical algorithms, and extensive visual and audio feedback capabilities. It allows users to extract meaningful information from their measured 3D data, automate the inspection process when more than one piece is measured, and structure the presentation of measurement results to facilitate enterprisewide digital collaboration.

Market-Leading

Portable Metrology Platform

Renowned for the power and stability of its direct hardware interfaces, PolyWorks|Inspector offers an extensive set of guidance technologies that the world’s largest manufacturing OEMs trust to implement efficient, precise, and repeatable measurement processes for portable metrology devices.

Technical Specification

Minimum System Requirements*

*These requirements are adequate if you are planning to use single-point probing devices and your CAD model file sizes are smaller than 50 MB.

Recommended System Requirements*

*This configuration covers a broad range of applications by offering the performance required when importing larger CAD models or laser scanning large parts with high resolution. If you have doubts about the best system configuration for your type of application, contact our technical support team.