3D Services

3D Scanning Services

Digital Scan 3D LLC (DS3D) has the experienced staff to perform any 3D scanning, Reverse Engineering and Quality Assurance projects. Our technological expertise covers a variety of different technologies, including Blue Light, White Light, Blue Laser Line, and Vertical-Cavity Surface-emitting Laser (VCSEL).

Accuracy

We offer the highest accuracy in the industry depending on the 3D Scanner used. Most of our 3D Scanners have accuracy ranging from 0.01mm to 0.1mm (0.0003” to 0.004”). When scanning your products, we will select the right technology that delivers the most optimal accuracy, speed and resolution you need for your application.

Types of 3D Scanning File Output

We can provide almost any/all industry standard file output:

.STL, .OBJ, PLY, WRL, .ASC, .AOP, .PTX, .XYZRGB, .e57

Types of 3D Scanning File Output

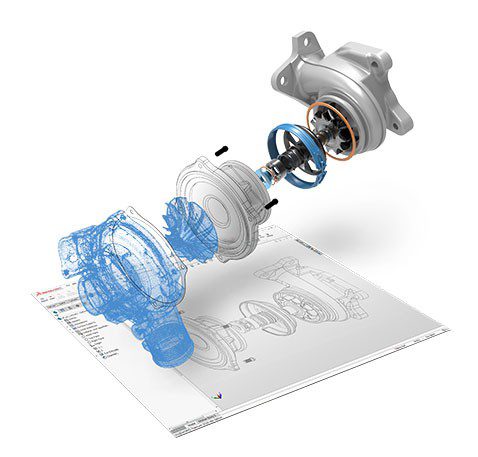

Reverse Engineering Services

Reverse Engineering (3D Scan based) is the process of reproducing a part by extracting surfaces or sketches from a scanned point cloud/mesh to create a CAD model of the part. Modeling methods such as prismatic/mechanical or organic are used to best recreate and reflect how the part was designed originally. Creating a 3D CAD model from a 2D drawing to reflect design intent is also another form of reverse engineering. Reverse engineering is becoming a more popular method of creating a 3D model of a part without existing CAD files. This process has saved lots of individuals and companies’ time, cost and increased quality on design processes and time to market.

3D Scan to CAD Reconstruction

Quality Assurance Services (QA/QC)

Digital Scan 3D LLC (DS3D) has highly trained and experienced staff to perform practically any inspection service project.

We can inspect and analyze your parts in a variety of ways:

Inspecting 3D Scanned Parts to CAD

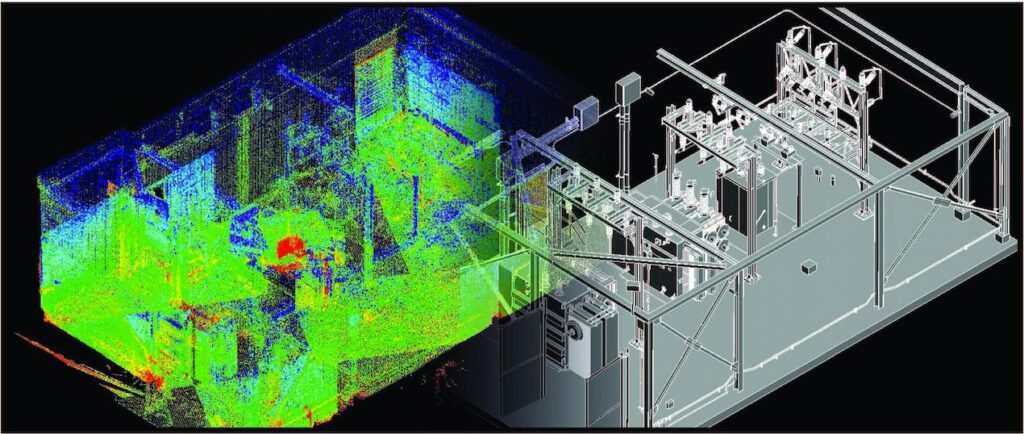

Building Information Modelling (BIM).

Building Information Modelling (BIM) is a digital representation of the physical and functional characteristics of a facility. BIM is a shared knowledge resource for information about a facility forming a reliable basis for decisions during its lifecycle, from inception onward. It provides a more efficient method for designing, constructing, and managing buildings and infrastructure.

Our BIM services bring designs to life, fostering collaboration, efficiency, and accuracy throughout the project lifecycle. 3D Laser Scanning division embodies industry-leading expertise, housing skilled professionals with immense domain knowledge that positions us as pioneers in 3D Laser Scanning services. Employing laser triangulation, a sophisticated technique utilizing directional light sources and video cameras, we achieve precise and comprehensive data acquisition. Our BIM solutions to witness how innovation meets construction.

Revolutionizing Building Design: BIM goes beyond traditional 2D drawings by creating parametric, intelligent models. Unlike static drawings, BIM operates on a dynamic digital database where any modification reflects seamlessly throughout the entire model. This collaborative approach synchronizes architects, engineers, contractors, developers, and building owners throughout the building life cycle, fostering different viewing perspectives and seamless information sharing.

Level of Detailing/Development (LOD)

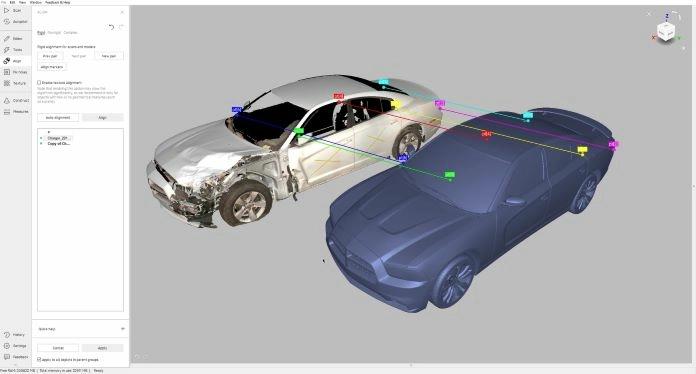

3D Scanning for Accident Reconstruction

Accident reconstruction involves determining the events leading to, during, and after a traffic collision. At Digital Scan 3D LLC, we have a team of 3D scanning accident reconstruction professionals that can create precise and detailed models of accident scenes. These models provide invaluable data for analysis, helping to understand the dynamics of the collision and providing evidence for legal and insurance purposes.

Key Features of 3D Scanning in Accident Reconstruction