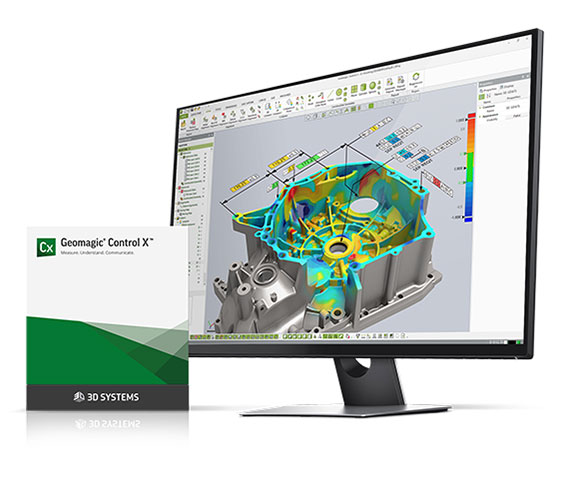

Geomagic Control X

The Ultimate Inspection Solution

Geomagic Control X brings the power of 3D scan-based inspection to more people in more places with industry-leading metrology software that makes it easy to capture and interpret scan data.

Application

Special Features of Geomagic Control X

Gain Deeper Insights Beyond Pass/Fail

Design, Inspect, Manufacture

Geomagic Design X

Geomagic Control X 2024 gives users across the room, across the street or across the world simple and powerful inspection capabilities leading to better decision making, improved efficiency in inspection workflows and lowering overall risks and costs.

This latest release focuses on making the inspection process easier, allowing access to everyone who participates in the inspection process and enhancing features to provide greater productivity in metrology workflows.

Areas include:

See a sample inspection report for your review. If you have any questions, don’t hesitate to give us a call or email us.