Each micron matters when working with small mechanical parts, jewelry, dental models, or fine-detail parts. Selecting the best 3D scanner for small objects can be the difference between a perfect digital replica and a distorted representation. There are so many scanners on the market – how do you choose a scanner that meets your requirements?

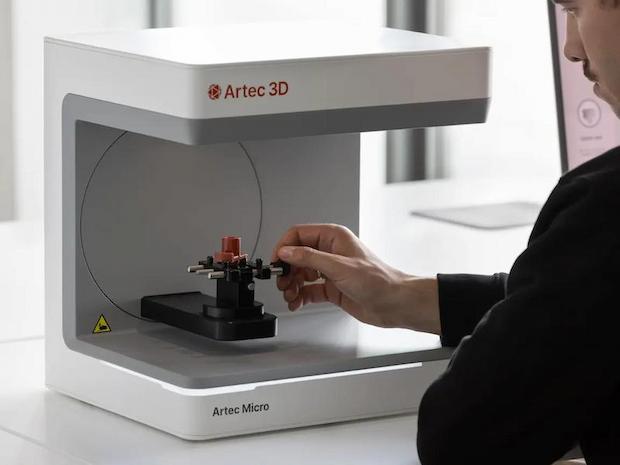

In this guide, we will outline the critical elements that determine accuracy, efficiency, and value in general, we will compare the top models like Artec Micro II to the ones that are more suited for professional applications.

1. Accuracy & Resolution: The Essence of Precision 3D Scanning

When it comes to scanning small objects, two specs to keep in mind are accuracy and resolution.

- Accuracy tells you how closely the digital model resembles the object in the real world.

- Resolution tells you how finely the scanner captures small features (edges, engravings, textures).

If you are scanning jewelry or other precise components, you want the following specifications:

- Accuracy of 0.01 mm (10 microns) or better

- Point resolution below 0.03 mm

For instance, the Artec Micro II has specifications of up to 5 microns of accuracy and 2 microns of repeatability, which is perfect for metrology-grade inspection, reverse engineering, and design work.

2. Object Dimensions & Working Zone

Not all scanners are equal when it comes to small items. Typically, mini parts go with desktop 3D scanners, and are likely to have had:

- A working zone of about 200 × 200 × 150 mm;

- Turntable or automated scan path.

Prior to purchasing anything, make sure that the scanners maximum object size is aligned with your most common part sizes since anything oversized will result in a blind spot or an incomplete scan.

3. Automation & Ease of Use

If you need to scan several parts in a day, automation is important. Systems like an Artec Micro II have:

- One-click scanning workflows,

- Smart scan paths that will identify the ideal angle automatically and

- Don’t require anything to be placed on the part (including stickers).

This gives you the benefit of speed and also minimized operators error, which is an important benefit when used in either production or quality inspection.

4. Surface Compatibility & Lighting Technology

Small parts usually have a more difficult surface to capture: shiny metals, transparent glass, or dark plastics.

To handle any difficult materials, look for a scanner that has:

- Blue or white structured light allowing for high detail capturing,

- Adaptive exposure depending on the reflectivity of materials, and

- LED based lighting and illumination to provide consistent lighting.

A scanner like the Artec Micro II, for example, is usable as RGB LED structured light, capturing both color and geometry in one scan — in most applications color need to be accurately captured (like jewelery).

5. Software Integration & Output Formats

A 3D scanner is only as good as the software that it uses. Select a scanner that has software which:

- Provides painted automatic alignment and noise filtering.

- Has compatibility with CAD software like SOLIDWORKS or Geomagic.

- Includes exporting files into common formats like STL, OBJ, or PLY.

An example is the Artec ecosystem, which includes Artec Studio, which processes and outputs clean mesh data directly in design and inspection products.

6. Cost vs. Performance

Base-level scanners tend to be inexpensive but often sacrifice accuracy or reliability.

In cases where you require repeatable precision for professional work, a metrology grade desktop scanner pays for itself quickly when you factor in rework savings, faster inspection processes, and reduced outsourcing.

While the Artec Micro II scanner is on the higher end of the price scale for scanners, it provides lab-grade accuracy and a completely automatic operation, which significantly reduces time spent in manual set-up and post processing.

Conclusion: Assessing Accuracy vs. Usability

Selecting a 3D scanner for small objects requires an equilibrium between accuracy, usability, and software efficiency. When scanning very small parts like micro mechanical parts or jewelry, a tool like the Artec Micro II offers the best mix of automation, accuracy, and flexibility today.

Contact Digital Scan 3D for a personalized recommendation or demonstration. Our specialists will help recommend an ideal 3D scanning solution for your application.

Important Points

- Prioritize accuracy (< 0.01mm) for very small, finely detailed objects

- Look for scanners that have automation and color capture.

- Be sure to consider software compatibility and workflow

If you are scanning to achieve high-end results, Artec Micro II remains one of the best options in 2025.