Introduction

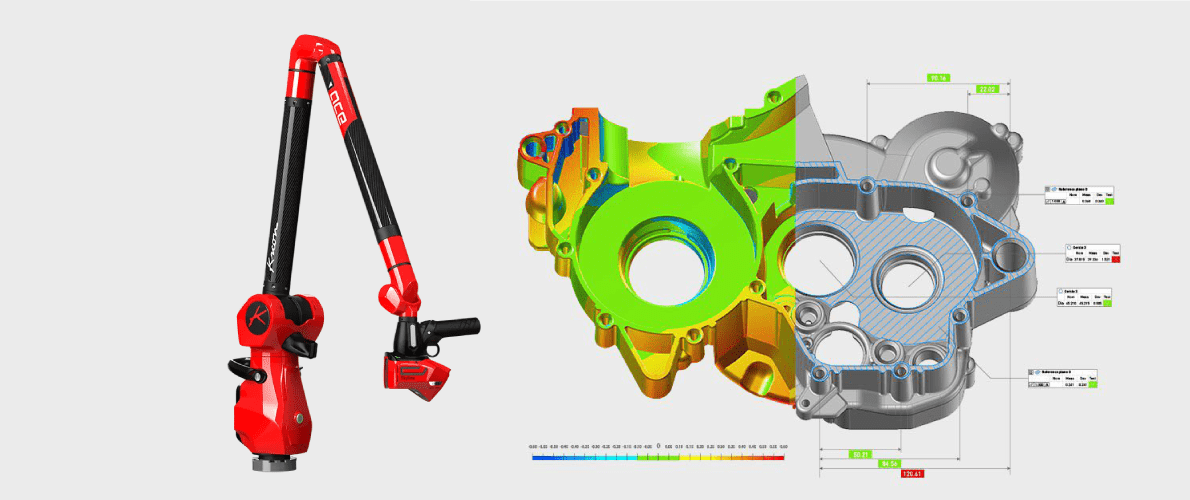

Reverse Engineering is essential in product design, legacy part replacement and competitive benchmarking. As a function of 3D construction, reverse engineering requires more advanced measurements of the real world than traditional measurement devices are capable of delivering. The Kreon Arm CMM 3D Scanner provides some of the best technology for reverse engineering available today.

Why Reverse Engineering Needs 3D Scan Technology

While Reverse Engineering can simply aid reconstruction of an exact object, for many applications, it is necessary to extract the information from the object so that it can be better understood or innovated upon, optimized or integrated into another object. Historically reverse engineering has been done with manual instruments, including traditional calipers or CMM systems. Both examples taken are too slow to analyze the correct measurements for modern complex geometries.

How the Kreon Arm Can Change Reverse Engineering

Users of the Kreon Arm will experience the benefits of using high resolution laser 3D scanning combined with tactile probes to capture every feature, including sharp edges and soft organic curves.

1. The Kreon Arm will capture all geometries very accurately.

- Greatly improved speed and detail scan geometric and freeform surfaces.

- Can Capture millions of points and provide rich point cloud data at every scan.

- Accommodates reflective materials and dark surfaces better than alternative systems.

2. Fast / Seamless scan to CAD technology

- Exported scans in Geomagic Design X or SolidWorks easily allows the conversion of point clouds to editable parametric CAD models.

- Skip the manual tedious operation of modeling non-complex geometries.

3. Flexibility with Hybrid Scanning

- Touch probe for capturing holes, edges and hidden features

- Scanner for capturing smooth curves and surface profiles

- Choosing a scan method can be determined by part geometry

4. Integration into Digital Twin Workflows

- Ideal for digital twins for simulation and product lifecycle management (PLM)

- Ensures legacy parts can be scanned and transferred to the modern design framework

Case Study: Redesigning a legacy automotive bracket.

An engineering company utilized the Kreon Zephyr III + 7-axix arm to scan and recreate a legacy bracket:

- 1 hour3D scanning

- 3 hours to a full parametric CAD model

- Prototype 3D printed the same day

- Saved the company an estimated 3 days of manual measuring and modelling without accuracy guarantees.

Industries Seeing the Value of Kreon 3D Scanner for Reverse Engineering

- Automotive: Tooling, body panels, engine parts.

- Aerospace: Turbine blades, brackets, airframe parts.

- Medical: Custom prosthetics and implants, anatomical modeling.

- Manufacturing: Molds, dies, jigs and fixtures.

Education Benefits Recap

- Reduced turnaround / project timelines for reverse engineering.

- Higher fidelity digital models.

- Reduction in errors, measurement and labor.

- Speed up the redesign / customization process.

Conclusion

The Kreon CMM Arm 3D Scanner is more than just a tool for reverse engineering projects — it is more of an enabling device that can transform any individual working in reverse engineering. Hybrid scanning modes, advanced software compatibility and performance precision are just the beginning of what Kreon allows! Other uses of the Kreon CMM Arm include but not limited to Quality Assurance and Control (QA & QC).