Artec Point

Metrology-grade handheld laser 3D scanner

Laser scanner for metrology capture in the palm of your hand

Artec’s first target-based 3D laser scanner introduces ISO-certified, metrology-grade 3D scanning to your workflow. Artec Point rapidly captures complex surfaces – even those featuring black or shiny exteriors – with up to 0.02 mm accuracy for quality control and reverse engineering.

Alternate between grid, parallel, and single-laser modes to maximize results and use HD cameras fixed at a steep viewing angle to capture in narrow areas. With a light yet robust metal chassis, the Artec Point is also versatile for use in demanding industrial environments.

When it comes to capturing intricate objects with high repeatability and pinpoint accuracy, Artec Point always delivers, making it the ideal solution, wherever you need fast, reliable data.

Technical specification

| Scanner type | Handheld |

| 3D light source | Blue laser, class II (eye-safe) |

| 3D point accuracy, up to | 0.02 mm (0.0008 in) |

| Volumetric accuracy, up to | 0.015 mm + 0.035 mm/m (0.0006 in + 0.0014 in/ft) 0.015 mm + 0.015 mm/m with Artec Metrology Kit (0.0006 in + 0.0006 in/ft) |

| Weight | 570 grams (20.1 oz) |

| Scanning rate, up to | 2.8 million measurements/s |

| Capture rate, up to | 120 FPS |

| Scanning area | 700 × 600 mm (27.6 × 23.6 in) |

| Depth of field | 550 mm (21.7 in) |

| Size of scanning object/area | S–L |

| Certification | ISO 17025 accredited based on VDI/VDE 2634 & JJF 1951 |

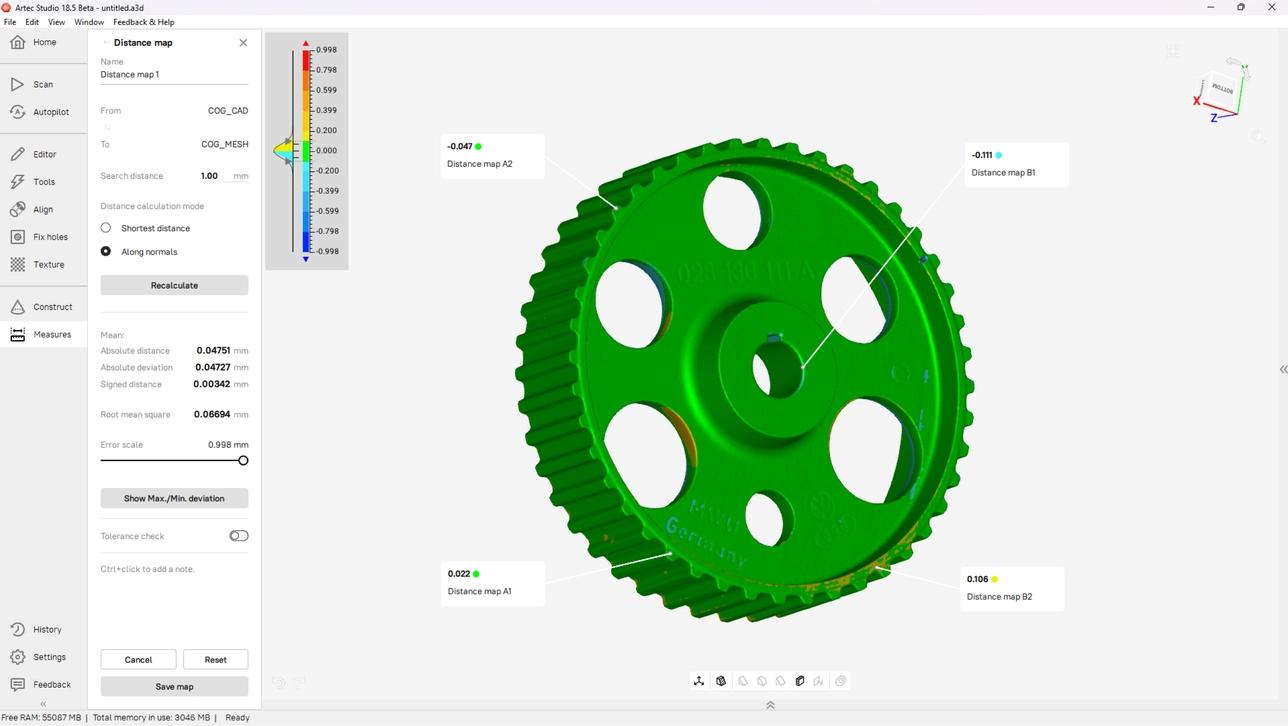

Stunningly accurate models – every time

With super high accuracy, solid tracking, and dedicated modes for complex geometries, the Artec Point 3D scanner captures highly repeatable metrology data you can count on.

Perfect for metrology 3D scanning

Meet Artec Point

Find out how the Artec Point 3D laser scanner can benefit your particular industry or application with a live demo, in person or online.

Adapt to different surfaces in a single click

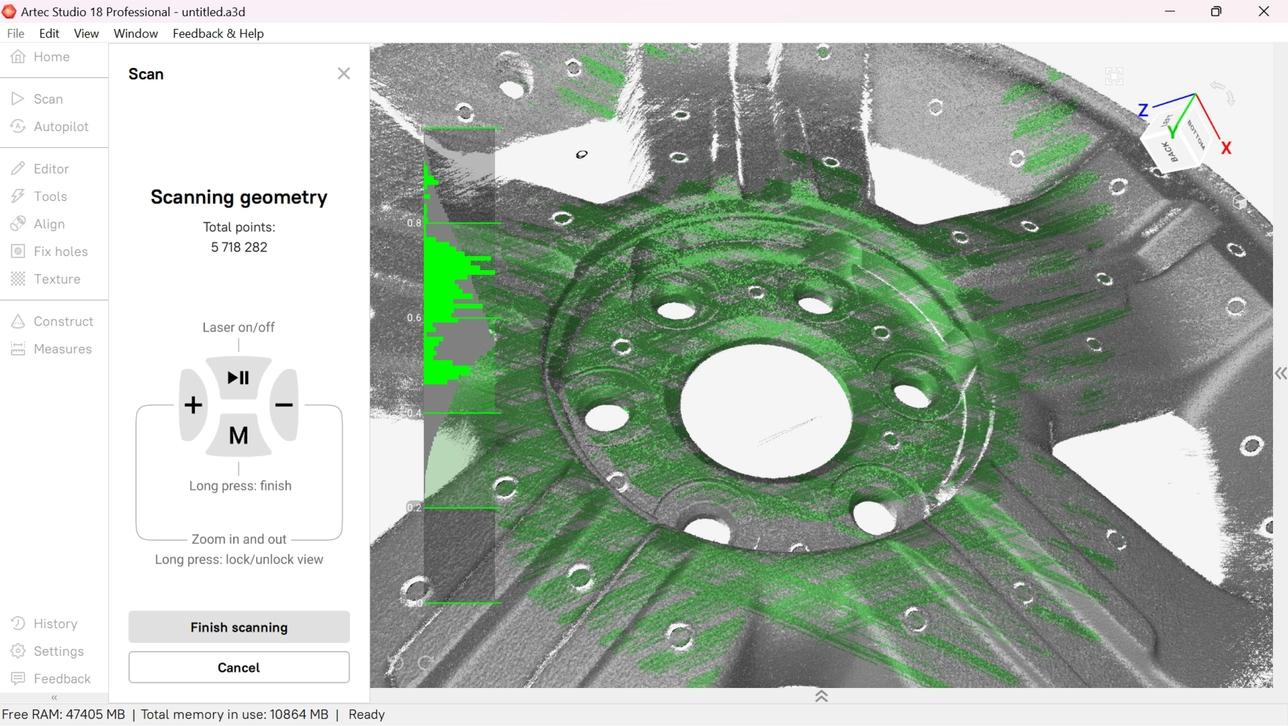

Artec Point’s three modes allow you to switch between scanning large objects at pace, capturing intricate details, and digitizing deep holes, at the click of a button.

Accelerate your workflow using a 17 x 17 crossed-laser grid that accurately captures large objects at pace, and keep poly-count to a minimum for lightweight 3D models.

Deploy 7 parallel lasers to digitize complex surfaces in high resolution, detect more intricate details like engraved features, and get the data needed for advanced metrology tasks.

Scan with a single laser to maneuver into hard-to-reach areas and capture data exactly where you need it – even inside deep grooves or holes, for quality inspection and reverse engineering.

Artec Studio

Applications

Industries

With metrology-grade accuracy and a lightweight, versatile design, the Artec Point 3D scanner can be applied across industries, but it’s best suited to the following: